Milling Speed and Feed Calculator

Our free speed and feed calculator can be used to determine the spindle speed (RPM) and feed rate (IPM) for the specified cutting conditions, as well as the cut time ...

WhatsApp)

WhatsApp)

Our free speed and feed calculator can be used to determine the spindle speed (RPM) and feed rate (IPM) for the specified cutting conditions, as well as the cut time ...

critical speed of ball mill – Ore equipment: ore crusher, ore . Ball mill critical speed, ball mill efficiency. What is the ball mill critical speed and how to ...

2 Flute Ball End Die and Mold Tools ... Speeds and Feeds to be considered as a starting ... For starting speed using a ½" 4 flute end mill cutting Titanium at a ...

End Mill, Drill, and Cutting Tools Manufacturer Melin Tool Company Premium Cobalt HSS and Carbide Endmills, Drills, and Cutting Tools

ABSTRACT: In this study, the effect of fraction of mill critical speed was investigated on the limestone and the clinker samples using Göltaş cement factory ...

How to optimize a 6 pound ball mill to safely and effectively ball ... Quick Easy Black Powder Ball Mill ... optimum material load, and optimum milling speed. ...

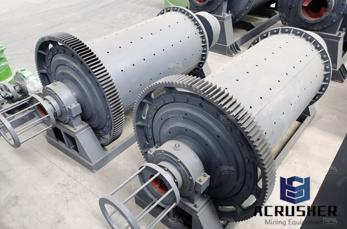

Ball Mill Manufacturers In Indiaball Mill For Sale. Ball Mill manufacturers in Mill critical speed design in India India ball mill ...

Buy High Performance End Mills | Atlas Cutting Tools Custom ... Cobalt and High Speed End Mills all USA ... Ball Nose End Mills are best for machining ...

critical rotational speed ball mill_Ball Mill Critical Speed Calculation mill critical speed grinding critical speed ball mill ...

What it is the optimun speed for a ball mill ? posted in Pyrotechnics: I have done a ball mill, recenly finished, but the motor has too rpms, is too fast for use ...

https:// Learn about Ball Mill Critical Speed and its effect on inner charge movements. The effect of Ball Mill .

Jul 17, 2013· high speed ball mill – Grinding Mill China. Ball mill Wikipedia, the free encyclopedia. A ball mill is a type of grinder used to grind and blend ...

Coal pulverizers may be classified by speed, as follows: Low Speed; Medium Speed; High Speed; Low Speed Ball and tube mills. A ball mill is ... Get Price.

Mini Planetary Ball Mill is an ideal facility to acquire research samples for research institutes, universities as well as enterprise laboratory which needs to ...

A ball mill can grind and homogenize small sample volumes down to the nano range. The Emax is an entirely new type of ball mill for high energy input.

High speed machining (HSM) using ball nose end mills, is attracting interest in the aerospace industry for the machining of complex 3D aerofoil surfaces in nickel ...

A ball mill is a type of grinder used to grind and blend materials for use in mineral ... Critical speed can be understood as that speed after which the ...

how to determine mathematically critical speed of a ball mill., ball mill is a type of grinder used to grind materials into extremely fine powder for use in ...

A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell''s inside ...

Paul O Abbé Equipment Company is a manufacturer New Steel Ball Mills and Milling ... rotational speed, media size and milling duration can be ...

Experiments are designed using Taguchi method to find the optimum parameters for silica sand nanoparticles production using low speed ball milling. Orthogonal array ...

The MSKSFM3 (Updated since 7/17/13) is a compact high speed vibrating ball mill for making small quantity of powder samples at easy and fast with improved vibration ...

Ball Nose milling application information. Feed, speed and diameter compensation. Recommended ball nose cutting speeds. Troubleshooting.

This paper describes the development of a simulation model for ball end milling with inclination angle based on a finite element method. The Johnson–Cook model and ...

WhatsApp)

WhatsApp)