operating ball mill efficiency

An alternative to increase the efficiency of ball mills Despite its rudimentary operating principle, ball mills are the mineral grinding devices ...

WhatsApp)

WhatsApp)

An alternative to increase the efficiency of ball mills Despite its rudimentary operating principle, ball mills are the mineral grinding devices ...

calculations define the efficiency of a fine stagecrush ball mill circuit as ... operating with an efficiency of or ... Secondary crushing: worth the cost?

Ball mills account for the majority of all ... cement mill; Optimizing the ... on relevant industrial efficiency technologies or measures that are not ...

Effect of Slurry Solids Concentration and Ball ... utilize the available mill capacity and maintain energy efficiency for these ... ball mill at different operating

not meet design throughput at the design operating conditions of ball and rock charge, ... Ø SAG mill efficiency was highly dependent on recycle crushing.

1 Metallurgical Plant Design and Operating Strategies (MetPlant 2013) 15 17 July 2013, Perth WA Energy Efficient Ball Mill Circuit – Equipment Sizing

Improving The Efficiency Of Fine Grinding ... The high energy efficiency of stirred mills compared to ball mills is well ... mill operating with grinding ...

measuring the efficiency of the tumbling mill as a function of lifter configurations and operating parameters by husni usman

Equipments Producing High Efficiency Limestone Grinding Ball Mill,Operating Cost Is Low Wet Pam Mill, Find Complete Details about Equipments Producing High ...

1. Introduction. Ball mills are the most common and versatile type of tumbling mill. They are remarkable in that they can operate over a very wide range of conditions ...

CALCULATION OF BALL MILL GRINDING EFFICIENCY International . Please can anyone give me, step step by procedure on how to work out on cement ball mills to. .

Ball Mill Bb27 Operating Manual. Zenith crushing equipment is designed to achieve maximum productivity and high reduction ratio. From large primary jaw crusher and ...

grinding mills. Grinding mills ... renowned SAG and Ball Mills operating in some of the most extreme environments. The Vanderbijl ... quality of the operating mill.

operating ball mill efficiency. The determination of the efficiency of the milling process SAIMM. parison with ball milling results thus yields a value for the ...

The current process configuration at the Huckleberry operation is based on a SAG mill operating with a pebble crusher and ball ... in stirredmill energy efficiency.

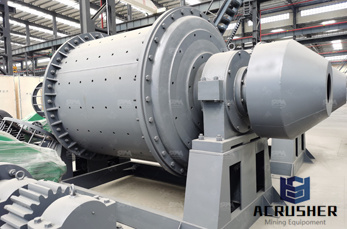

Ball Mill. Ball mill and rod mill is very good for grinding ore into fine dust particles. However, improved efficiency, largescale mining projects, including the ...

Ball Mill Low operating costs – Stone Crusher Machine . The design of this series was geared to optimized production, operating and maintenance costs.

Ball mill Wikipedia, the free encyclopedia. A ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing ...

The harder the media the better the grinding efficiency and consequently, ... The theoretical critical speed of a ball mill is the speed at which the centrifugal ...

cataracting in ball mills Grinding Mill China. cataracting cascading cement mill howShanghai Caiman Machinery . Grinding Mill. MTM medium speed trapezium mill ...

THE INFLUENCE OF MILL SPEED AND PULP DENSITY ON THE GRINDING EFFICIENCY 89 Pilot plant description The milling pilot plant consists of two .

Energy Savings and Improved Recovery with Small ... Small Media, Fine Grinding, Ball Mill, ... a Vertimill pilot mill showed the better efficiency of

The specific selection function effect on clinker grinding . efficiency in a dry batch ball mill . ... observations showed that ball diameter, as an operating ...

Ball Mills Ball Mills, and other forms of tumbling mills such as tube mills, rod mills and batch mills form a significant type of equipment used for the size ...

WhatsApp)

WhatsApp)